3D printer

coming soon

Custom closet & loft bed

After grad-school I moved back home while looking for work. In my time away I had accumulated a bunch of stuff that quickly filled my old childhood bedroom. Luckily, the room had a vaulted ceiling which meant that I had untapped space available if I could find a way to access it. At my friend’s suggestion I looked into purchasing a loft bed; however, none of the designs would utilize the space as efficiently as I wanted so I decided to build one myself.

1) Rust removal through electrolysis

Electrolysis is a process in which there is an exchange between atoms due to oxidation (loss of electron) and reduction (gain of electron) from an external power source.

If we put two conducting posts into a body of water, connect one post to the positive terminal of a battery and the other post to the negative terminal, electrolysis will occur. At the negative terminal (cathode), electrons are supplied, given to the surrounding water, reducing it. Subsequently, at the positive terminal (anode) electrons are taken from the surrounding water, oxidixing it. This process turns our body of once "pure" water H2O into a mixture of liquid water, hydrogen gas, and oxygen gas:

H2O -> H2O + H2 + O2

Rust is a combination of iron (Fe) and oxygen (O) in the form Fe2O3. To remove rust from an object we simply need to make the object our cathode by connecting it to the negaive terminal of our power source. Now, by supplying electrons to the rust we can separate iron and oxygen through reduction:

2Fe2O3 -> 4 Fe2+ + 3O22-

The separated oxygen gas is now free to combine with the hydrogen gas to once again form water, leaving you with your original iron object.

Fe2O3 + 3H2 = 2Fe2+ + 3H2O

Notice that the recalimed iron is still slightly charged meaning that it is prone to rusting again in the future. To solve this we can coat the blade metal less susceptible to corrosion like aluminium, nickel, zinc, or copper.

2) Electroplating to prevent future rusting

Electroplating a type electrolysis in which we take coat an object (substrate) in a thin layer of metal. This is done by connecting the plating material to a battery's anode (+) and the substrate to the battery's cathode (-). By supplying a constant voltage negatively charged and positively charged ions (anions and cations) transfer to the anode and cathode respectively, evenly coating the desired part.

For this project I used electroplating to coat the blade in a layer of nickel.

Hand plane blade restoration

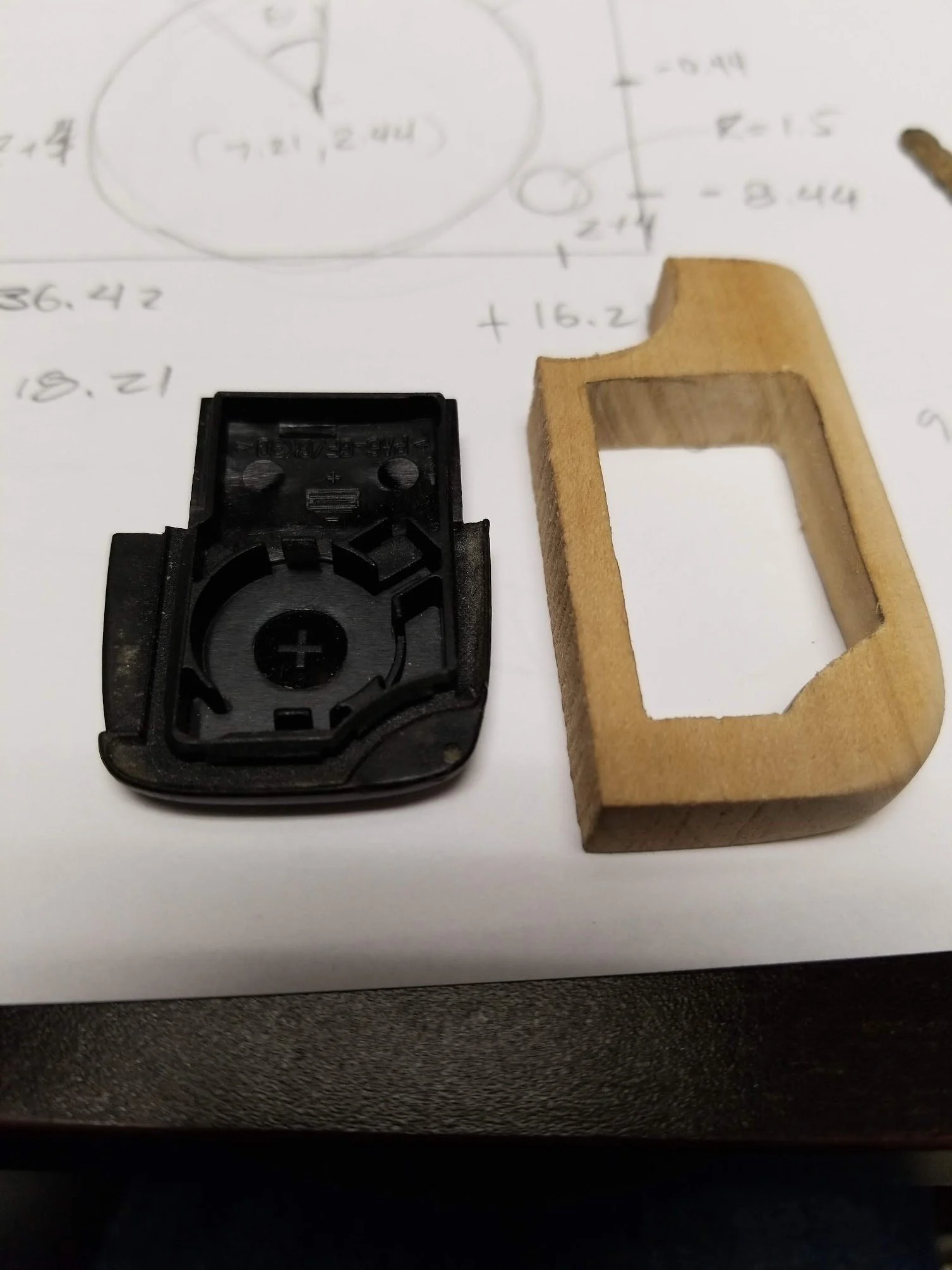

Wooden keyfob

I thought it would be cool to make a wooden keyfob, but then I got rear ended.